Fabrication

Nova’s AISC-Certified fabrication shop and in-house engineering staff provide a significant value to our customers.

AISC certification is only conferred on operations which have the facilities, properly trained personnel, organization, tools and quality controls in place to meet the rigorous AISC standards. Our shop has demonstrated year after year that it meets those standards, providing us with the ability to fabricate structural steel for complex applications at a substantial cost and time savings for our customers. Even more impressive is the safety record for the shop, which has gone more than five years without a single lost time accident!

Nova also holds certifications through ASME and government agencies to manufacture pre-insulated piping systems, containment piping and prefabricated piping, with extensive experience in the design and fabrication of double containment piping systems. We have engineered, manufactured and installed over one million feet of Class A steam and condensate piping systems and are the only company in the United States that both manufactures and installs these systems.

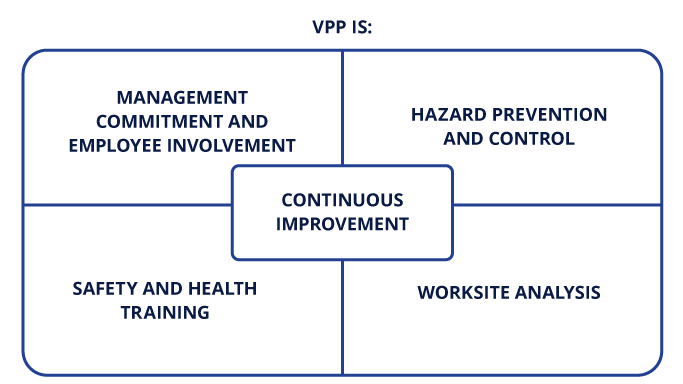

Nova’s Napa, CA fabrication facility achieved VPP (Voluntary Protection Plan) Star Site status on 2018. We have teamed with CAL/OSHA to become the first fabrication shop in CA to achieve this status. Our commitment to the VPP principals has taken our shop safety culture to the next level.

In-House Engineering

Nova’s full time, in-house engineering staff includes:

- Mechanical Engineers

- Civil/Structural Engineers

- Electrical Engineers

- Drafting Staff

3D CAD Modeling is standard for all projects. Our engineering team saves time and cost by catching design and fabrication problems before materials are even purchased.

AutoCAD AEC Collection is utilized including Plant 3D, Advanced Steel, Civil 3D, and AutoCAD 3D.

Nova’s fabrication team includes:

- AISC Certified Fabricator (SBE – Simple Bridge Endorsement) 27+ years

- AMPP/SSPC QP3 Certified Coating Shop

- B31.3 certified pipe welders

- D1.1 and D1.5 certified structural welders

- Multiple fabrication areas with bridge cranes

- 40+ years of fabrication experience

COMMERCIAL AIRCRAFT HYDRANT FUELING PIT

Nova’s standard commercial hydrant fueling pit consists of a unique milk bottle shaped molded fiberglass shell, and a cast aluminum lid assembly rated to support aircraft wheel loads. The innovative fiberglass shell design provides a large 36″ diameter shell body enabling maintenance personnel to easily access the hydrant valve. The sloped pit floor provides a natural sump for the efficient removal of both spilled fuel and water. The pit design allows for a standard bottom pipe penetration or a side wall pipe penetration complete with a single or double Buna-N-Rubber boot. The cast aluminum lid assembly consists of an outer ring complete with pretaped holes for lifting eyes, and a hinged lid which opens 180 degrees. Both the lid assembly ring and lid come complete with a fuel resistant O-ring seal in a machined groove for a water resistant seal.

COMMERCIAL AIRCRAFT HYDRANT FUELING PIT

Nova’s standard commercial hydrant fueling pit consists of a unique milk bottle shaped molded fiberglass shell, and a cast aluminum lid assembly rated to support aircraft wheel loads. The innovative fiberglass shell design provides a large 36″ diameter shell body enabling maintenance personnel to easily access the hydrant valve. The sloped pit floor provides a natural sump for the efficient removal of both spilled fuel and water. The pit design allows for a standard bottom pipe penetration or a side wall pipe penetration complete with a single or double Buna-N-Rubber boot. The cast aluminum lid assembly consists of an outer ring complete with pretaped holes for lifting eyes, and a hinged lid which opens 180 degrees. Both the lid assembly ring and lid come complete with a fuel resistant O-ring seal in a machined groove for a water resistant seal.

COUNTERWEIGHTED VALVE PIT

Nova’s counter weighted valve pits are used to house military hydrant valves, large isolation valves or surge suppression equipment in aircraft traffic areas.

Nova’s counterweighted valve pit consists of a molded fiberglass shell and a counterweighted cast aluminum lid assembly rated to support aircraft wheel loads. The shell design incorporates deep corrugated fiberglass walls engineered for construction loads during concrete embedment. The large overall size is designed to economically provide maximum clear span working area while providing clearance for the counterweight assembly. The actual inside dimensions of the pit can be customized to the specific on-site requirements of the project. The sloped pit floor provides a natural sump for the efficient removal of both spilled fuel and water. The pit design allows for both sidewall and bottom pipe penetrations, complete with a single or double Buna-N-Rubber boot.

The cast aluminum lid assembly consists of a 25″ x 75″ or a 41″ x 75″ lid rated for aircraft wheel loads, and a counterweight lift assembly requiring a maximum lift force of 35 lbs. to open the lid. The cast aluminum lid is provided with a neoprene seal in a machined groove for a water-resistant seal. The opening latch mechanism is a simple button type operation, requiring the pushing of one of the two flush-mounted buttons. A safety catch is provided to engage when the lid is opened and to prevent a lid from closing until the catch is disengaged by the operator. The large lid size provides easy access to operating valves and the removal or repair of valves or surge suppression equipment.

COUNTERWEIGHTED VALVE PIT

Nova’s counter weighted valve pits are used to house military hydrant valves, large isolation valves or surge suppression equipment in aircraft traffic areas.

Nova’s counterweighted valve pit consists of a molded fiberglass shell and a counterweighted cast aluminum lid assembly rated to support aircraft wheel loads. The shell design incorporates deep corrugated fiberglass walls engineered for construction loads during concrete embedment. The large overall size is designed to economically provide maximum clear span working area while providing clearance for the counterweight assembly. The actual inside dimensions of the pit can be customized to the specific on-site requirements of the project. The sloped pit floor provides a natural sump for the efficient removal of both spilled fuel and water. The pit design allows for both sidewall and bottom pipe penetrations, complete with a single or double Buna-N-Rubber boot.

The cast aluminum lid assembly consists of a 25″ x 75″ or a 41″ x 75″ lid rated for aircraft wheel loads, and a counterweight lift assembly requiring a maximum lift force of 35 lbs. to open the lid. The cast aluminum lid is provided with a neoprene seal in a machined groove for a water-resistant seal. The opening latch mechanism is a simple button type operation, requiring the pushing of one of the two flush-mounted buttons. A safety catch is provided to engage when the lid is opened and to prevent a lid from closing until the catch is disengaged by the operator. The large lid size provides easy access to operating valves and the removal or repair of valves or surge suppression equipment.